DigiTwin for Pharma

DigiTwin for Pharma

Complete simulation of the FAT process, including the wet phase, without the need for water or manual cleaning before shipment

A Fully Simulated WET FAT with Zero Water Consumption with DigiTwin

At a Tier 1 European pharmaceutical manufacturer, MGA implemented a Digital Twin of a new skid composed of ProX90 (reverse osmosis) and EDI (electrolytic filter).

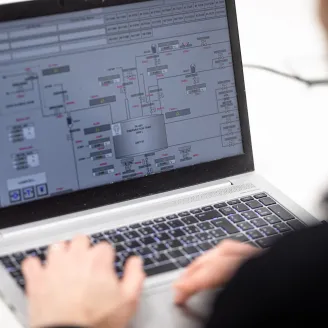

Using a physical PLC and a virtual HW-in-the-loop environment, the dynamic behavior of the machine was digitally simulated, allowing for advanced testing and unprecedented WET FAT optimization.

Client: Pharma Europa Tier 1

Location: Italy

Technologies: Digital Twin (HW-in-the-loop), PLC, Reverse Osmosis (ProX90), EDI

Scope: FAT simulation, automation testing, cost & time optimization